Veropal WSB E-LV epoxy stabilising resin

VEROPAL WSB E-LV is an extraviscous two-component epoxy stabilizing resin for stabilizing porous materials with large cracks or holes without the need for vacuum.

Detailed product description

VEROPAL WSB E-LV is a clear, extra low viscosity, two-component epoxy stabilizing resin for stabilizing porous, porous materials and wood with large cracks or holes without the need for a vacuum chamber. Certified for food contact. It is extremely thin, fluid, wicking, highly absorbent, virtually odorless. It bubbles away very well naturally. It has a long shelf life and a high ability to permeate materials. When cast (up to 5cm layer) and cured it produces a cast with a hard surface, minimal shrinkage and high gloss. It is also used as a suitable and highly durable finish for exteriors. It cures at normal temperature for approx. 1.5-2 days, at elevated temperature of approx. 75-80°C in an oven or furnace the curing time is significantly reduced (2-3 hours).

- Usage:

- Stabilization of porous and porous materials.

- Stabilization of soft, rotten, degraded wood and wood with large cracks.

- Casting of small to medium castings with layers up to 5cm (jewellery, clocks, boards...)

- It is also suitable for sealing pores in wood, it absorbs well into the wood.

- As a durable wood finish also for outdoor use.

-

Additional features:

- appearance after mixing components A and B - clear watery liquid

- dyeability - with suitable and compatible dyes and pigments (see PIGMENTS section)

- working temperature - ideally 19-23°C. It is possible to work at lower temperatures, e.g. (10-15°C), but it is necessary to take into account the prolongation of hardening with each step down. The downward temperature slows down the curing process, the upward temperature accelerates it. At elevated temperatures of approx. 75-80°C in the oven or kiln, the curing time is significantly reduced (2-3 hours).

- appearance after curing - clear, glassy

-

Packaging:

- 1.4 kg (ingredient A: 1 kg + ingredient B: 0.4 kg)

- 7 kg (ingredient A: 5 kg + ingredient B: 2 kg)

- 14 kg (ingredient A: 10 kg + ingredient B: 4 kg)

- Working procedure: first mix the two ingredients according to the weight ratio at normal temperature. For large pieces of material (e.g. wooden planks, wooden cakes, etc.) that cannot be placed in a vacuum or pressure chamber, first remove mechanical impurities. Then brush Veropal WSB E-LV resin repeatedly into the surface of the stabilized material until the material sucks. In the case of smaller pieces, these pieces can be placed in a container of stabilising resin and weighted down (or left to float in the resin and occasionally turned over repeatedly). In the case of highly porous materials, the resin level will drop significantly. It is necessary to check that the stabilised body is still below the resin level. When the material is saturated and no longer accepting more resin, allow it to cure at normal temperature (in the case of smaller pieces in the container, remove them from the resin outside and wrap them). Curing can be accelerated by the application of temperature. It has been successful to wrap the impregnated material in, for example, shrink wrap, so that the resin does not leak out of the pores unnecessarily during curing (take care that the temperature does not destroy the shrink wrap, in case of higher temperatures use foil wrapping). A vacuum chamber or a pressure chamber can be used to aid the seepage of the epoxy system.

- After the resin has cured and cooled, the stabilized material can be sanded and polished to its final appearance.

- The cured material must contain less than 10 % moisture. For complete drying of the material it is recommended to place the body in a 105 °C oven for a minimum of 12 hours (drying time depends on the size of the body). After drying, the body shall be sealed in a well-sealed container and allowed to cool. Do not put freshly dried hot material into the stabilising resin! Premature polymerization may occur and the body will not be properly stabilized.

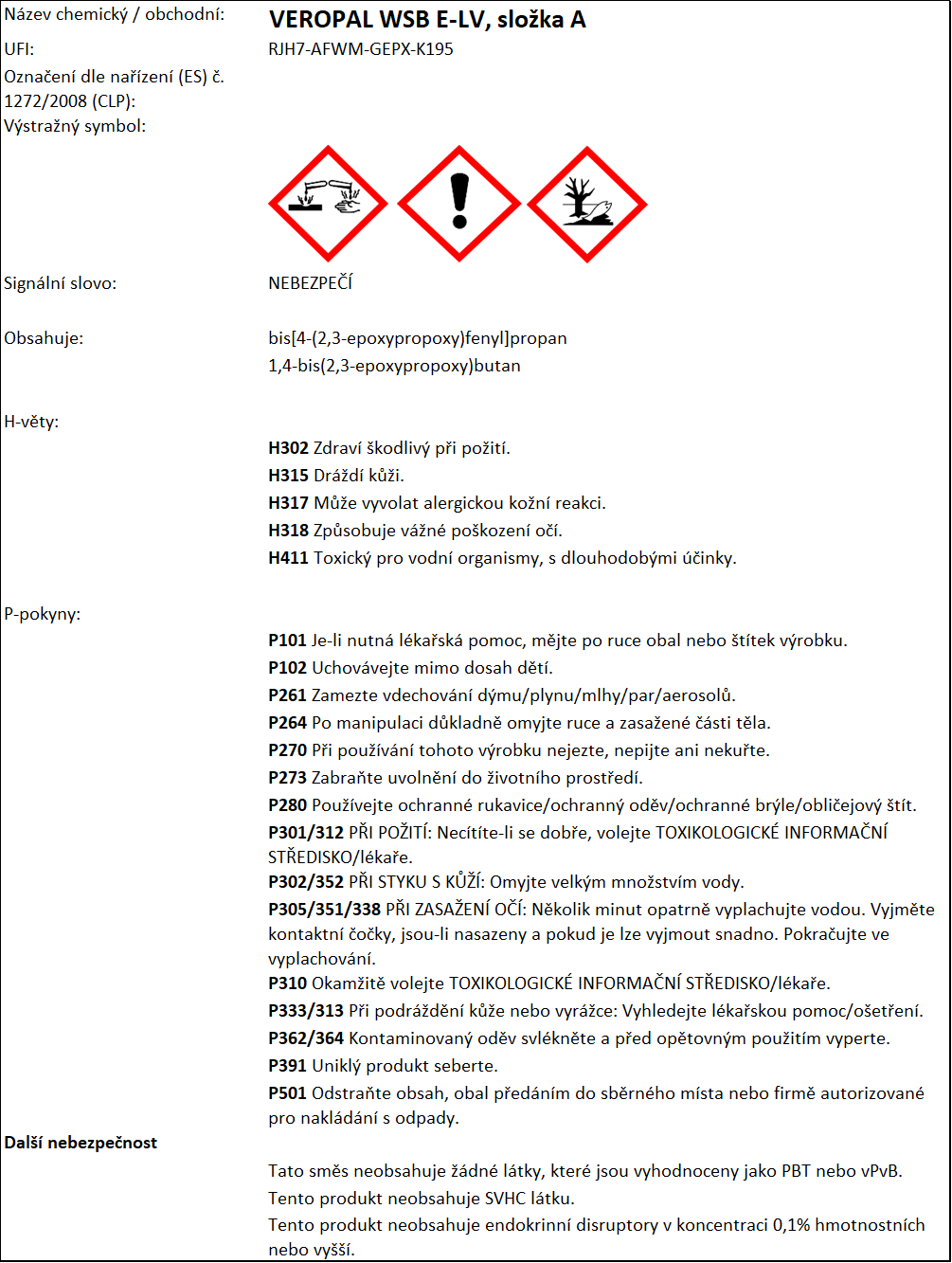

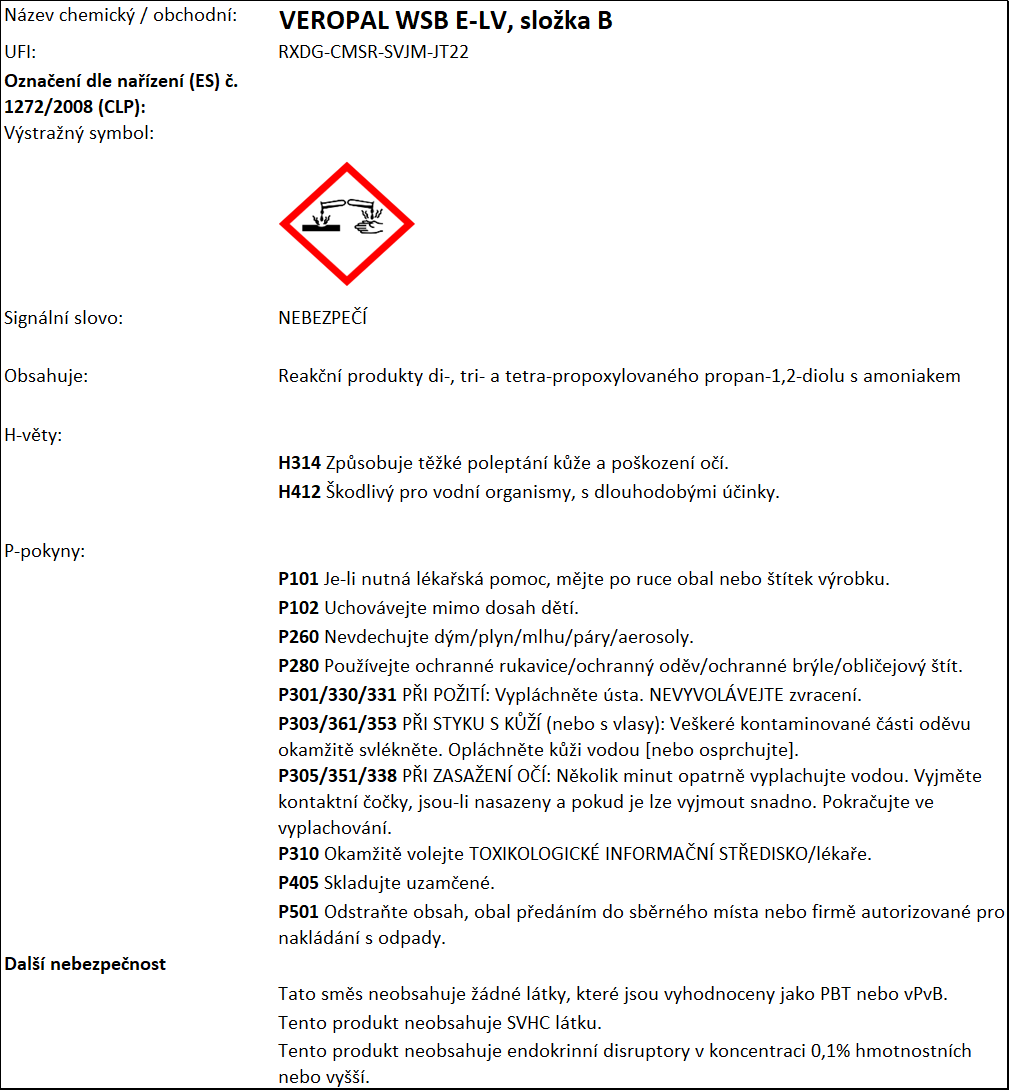

SAFETY NOTICE:

Be the first who will post an article to this item!

.png)